|

||||||||||

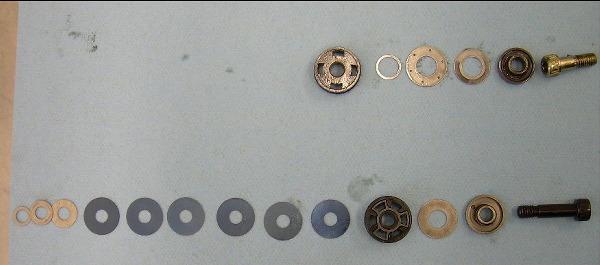

Top: Stock internals from a 900ss/sp fork. Bottom: Internals from a 748 - 998 fork. |

||||||||||

I attached the pics of your fork innards. The first pic is of the compression valve of the 900SS sitting above the 748-998 one. You will notice there is a HUGE difference between them . The 900SS valve is basically a piston port design, IE a hole. When the fork is in compression the three ports in the valve are the orifice that controls oil flow. Obviously very crude. There is nothing to allow for different damping rates based on shaft speed. So at low shaft speeds (a long rolling bump) it woks fine. It isn't trying to stuff too much fluid through the holes. But when you hit a sharp edge bump a lot more oil, going a lot faster is trying to get through the same size hole. This is what causes high speed harshness. It’s simply a matter of the fork being on the verge of hydro lock or in some cases actual hydro lock. The only thing that makes the 900SS valve a valve is that it does have a back flow "check valve" for when the fork is in its rebound stroke. The check valve is made up of the, starting from the right, the top hat, which locates the spring, which keeps the check plate (it's the one that looks like a shim with holes I it) sealed against the valve. When the fluid back flows it overwhelms that spring and the check plate opens. You will notice the 900SS only has 3 ports in it, which are working during both directions of flow. That's why the check valve plate needs holes in it. If not it would only flow in one direction. Clearly those little holes become a large restriction during high shaft speeds though. Another reason the forks are so harsh. The 748-998 valve is obviously a lot more complex, yet easier to understand the mechanics of (probably because it makes sense). You have a piston with 6 holes, 3 for compression, 3 for rebound. The back flow check plate doesn't need holes in it because it's only responsible for flowing fluid in one direction. The shim stack on the other side of the piston is what provides you with multiple damping curves based on shaft speed. At max shaft speed all of those shims will "blow off" and it will flow a large volume of fluid. But since there is a stack there it can also provide resistance to oil movement (damping) at low shaft speeds. The shim stack will open differing degrees depending on shaft speed. The more shims the more damping, less shims less damping. The biggest advantage the 748-998 valve has that it flows fluid in both directions without one direction interfering with the other. Even though the 748-998 valve is more complex it is actually a lot simpler to me. |

||

|

|||||

|

|||||

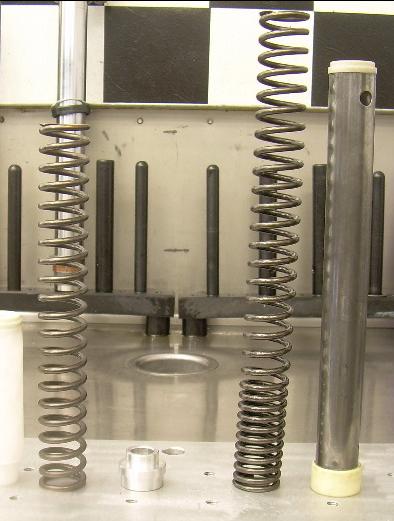

In the second pic (above) you will see the stack height of the old spring/spacer and the updated spring/spacer. The old one is on top. Obviously the old one is long. It goes from the top of the fork to the bottom. Note that the new spring setup has the cartridge in it for the pic. The spring is sitting on the perch I made that sits on the top of the cartridge. To get an idea of how big a change was made imagine that the old setup on top doesn't have the cartridge in it. If it did it would go all the way from the end of the spring on the left to abut 2" short of the spacer. When it is set up stock the spring and spacer don't touch the cartridge, the cartridge sits inside of the assembly. In the third pic (right) you can see how much shorter the spring is that I put in and how much shorter the spacer is. You can also see the spring perch I spun out. Note how the OEM spring is bowed in the middle, that's because it's so long. This pushes the spring against the inside of the fork tube when it is compressed. Net result, you now have a compression valve that works in compression and rebound without effecting the other and it will provide differing damping curves based on shaft speed/oil flow. The spring spacer assembly is a lot shorter which is first a foremost lighter, the spring doesn't rub on the inside of the tube and you have a Ohlins spring out of their R&T forks which is a lot more consistent than a stock one or even Race Tech. |

|||||

After it was all said and done I asked how these mods compared to switching over to a Superbike front end. Good question about the SBK forks compared to the modded SS forks. You're right the 900SS forks would technically be a bit more flexible than the SBK forks but you would need to be on some incredibly sticky tires and be right on the limit to tell. It's almost impossible to load them hard enough. Both forks have 20mm pistons so the basic architecture is the same. If you were to hold a SBK cartridge in one hand and a SS one in the other you wouldn't be able to tell the difference aside from the way the needle on the rebound circuit works. In the compression stroke your 900SS forks are virtually identical to a SBK fork. It would take one hell of a rider to tell the difference. The way the rebound circuit works in the two forks is different and the SBK one may have a slight advantage but the rebound circuit has such a simple job that it doesn't matter. Understanding there are no absolutes the rebound circuit only has one shaft speed to control. There is no high or low speed rebound (even if some stuff does have adjusters for it). Rebound is when the spring unwinds. No matter how fast you remove load from the front end the fork will rebound at the same rate. The spring pressure doesn't care how fast it unloads, it only unwinds so fast. Yes there is that little bit of crazy advanced tuning where you could play with things like trail braking characteristics with a low speed rebound circuit, but even the 12K Ohlins forks don't have an adjuster for that. So the short story is that your forks are as good as a SBK fork up to 95+%. And there are only a couple hundred guys in the US that could ride it that hard. As far as springing, which makes up a large portion of the forks performance goes you have a pretty big upgrade over the stock 900SS stuff and the SBK stuff. One last comment on this - there are some who might get so wound up on tech specs and theoretical advantages of one set up over another that they will take issue with something that's been said here. Please remember, we're talking about a streetbike here, being ridden by a guy who would starve to death if he had to make his living riding motorcycles. If you feel so strongly about something posted here that you have to respond, feel free. However, if your proof of why we're wrong involves comparing me and my 12 year old, two valve, air cooled, not current tech even when new 900ss to a current GP rider and his set up, you've missed the point entirely... at any given trackday there is some hotshoe on a clapped out SV650 who can lap me without breaking a sweat. Adjustable rebound damping isn't going to change that.. On the other hand, having a front fork that doesn't feel like a jackhammer on Michigan roads will be a nice thing. |

||